Typically occurring on busy projects where multiple mixes are being placed, placing non-compliant concrete mixes occurs quite frequently or at least more often than it should. Placing insufficient mixes can present significant safety issues and can be an extremely costly mistake. That is why it is critical to, first and foremost, check the batch ticket before anything else.

Placing the wrong concrete mix can result in issues such as insufficient compressive strengths or issues regarding air entrainment. Insufficient compressive strength mixes being placed is a prominent issue, usually resulting in additional non-destructive testing such as Windsor Probes or rebound hammer testing to identify the location of the non-compliant mix placed. Once identified, the engineer will often require cores to be taken of the non-compliant mix location to verify, if indeed, the mix does not meet the specified design strength, which may require complete removal and replacement.

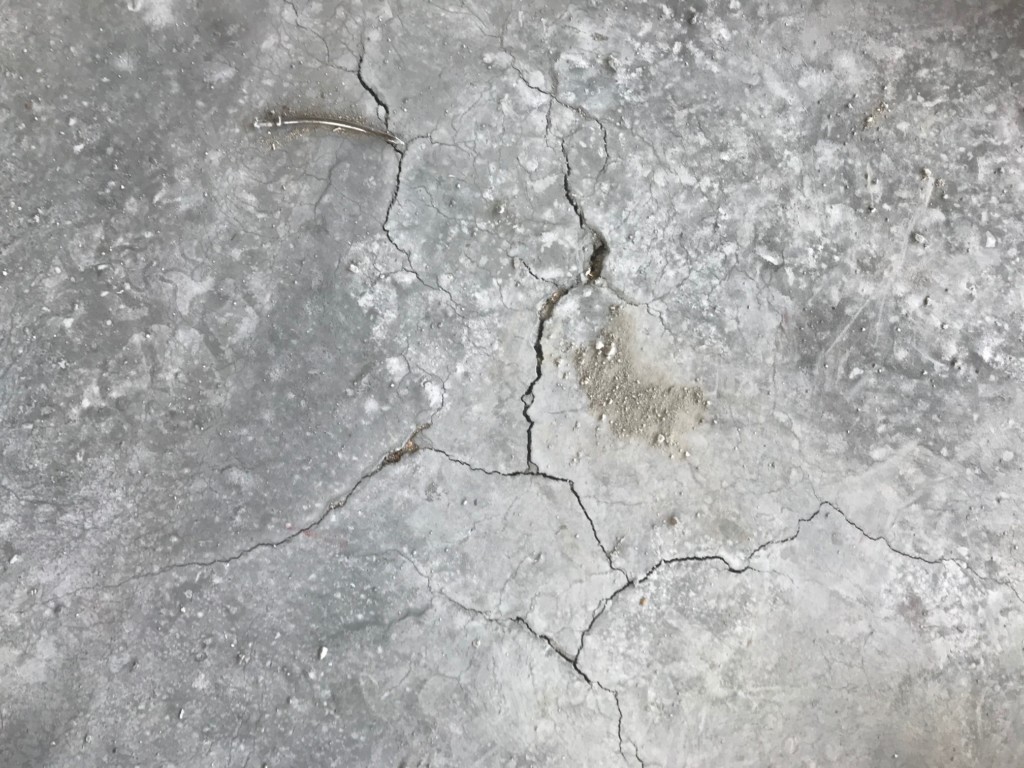

Placing an air-entrained mix that is not specified can lead to significant issues, especially on interior flatwork. Power-troweled air-entrained mixes typically do not work well together. There have been several case studies of hard-troweled air-entrained mixes with serious delamination issues, resulting in complete removal and replacement. The vice versa is true for non-entrained mixes used in cold weather climates leading to cracking and scaling from freeze-thaw cycles.

These issues can typically be avoided by doing a little pre-task planning prior to concrete placement. The following are some excellent ways to prevent or reduce the chance for non-compliant mixes from being placed:

- Set up a pre-pour meeting to discuss approved mix designs with all parties involved.

- Designate someone to collect and verify each concrete batch ticket before entering the placement location.

- Set up signs regarding the mix to be used at the placement location.

- Make sure the testing agency is performing all the required field testing (non-compliant test results can signal that the wrong mix is being used).

Placing an unspecified mix can lead to many more issues than identified above, but the key is to prevent it from occurring. A well-thought-out plan and communication amongst the parties involved can reduce the likelihood that this event will occur.